Today’s organizations see their procurement teams as a source of value that extends beyond cost savings. As a result, as a procurement leader, you are increasingly under pressure to improve the overall sustainability of your procurement operations. However, experienced leaders will not make big choices unless the necessary information is readily accessible. To get this information, they will need to monitor many procurement key performance indicators (KPIs) and the associated metrics.

What exactly is procurement KPIs?

A procurement KPI is a tool for measuring performance and monitoring and evaluating the effectiveness of a company’s procurement management. These key performance indicators (KPIs) assist firms in streamlining and optimizing their time, service quality, expenditure, and cost. Furthermore, procurement KPIs assist businesses in staying on track with their company objectives, goals, and overall procurement strategy.

Measuring procurement process efficacy is crucial because it affects the supply chain during economic downturns. In addition, procurement success is often linked to the cost-saving advantages it may give. Aside from cost savings, performance assessment may also assist firms in identifying areas of the company that needs improvement, determining how well they rank up against the competition and determining if they are expanding or decreasing as a corporation.

How Do You Pick the Best Procurement KPIs?

“What gets measured gets done,” as the adage goes in procurement. However, understanding what to measure and how to measure it is critical to the success of any performance management strategy.

The Initial Step

Select one or two metrics that relate directly to your procurement goals. Despite the various moving pieces essential to procurement operation and performance, tracking everything that happens inside is neither practicable nor efficient. For starters, not all metrics are valuable enough to monitor. Another issue is that having too many KPIs creates extra effort and confusion.

The idea is to choose one or two key performance indicators (KPIs) for your goals that will be most useful in accomplishing them.

The Next Step

Check that the chosen metrics match the criteria for a good KPI.

Make your KPIs tick by answering the following essential questions:

- Can it easily measure the chosen KPI?

- Is it easy to correctly and promptly measure the KPI?

- Is this KPI related to the overarching corporate goal and strategy?

- Can the KPI be used to influence or drive change without becoming excessive?

- Is the KPI comprehensive in terms of procurement perspectives?

- Finally, will the KPI hold up over time?

If the selected KPI replies “no” to several of these questions, it may indicate that the KPI needs to be changed.

The Third Action

Assign KPI responsibilities to the appropriate teams and people. KPIs are a valuable tool for monitoring progress, but they are most likely to produce results if someone is in charge of recording and reporting them.

In addition, the individual or team in charge is frequently more eager to see the measure succeed than tolerate underperformance. Allocating responsibilities in this manner increases the likelihood of success.

The Fourth Action

Keep track of and report on KPIs. Finally, monitoring your KPIs on a monthly, quarterly, or other set reporting interval is critical. Regular monitoring makes it simple to detect whether something has underperformed or outperformed and what may have happened over this time period to trigger the change.

It’s also critical to ensure everyone in the company is on the same page. Because many metrics and objectives are linked, discuss your results with all relevant stakeholders.

Procurement KPIs are required.

Key performance indicators (KPIs) are critical measurements used to assess some aspects of performance. KPIs allow project teams to track and communicate progress clearly and objectively. Procurement KPIs are more detailed and granular targets that may be tracked monthly or daily. Important performance indicators and critical outcome areas are often used interchangeably.

Key result areas (KRAs) are broad categories of results or outputs for which a process or function is accountable. The results of key result areas are the responsibility of a person or a group. The buying department’s major outcome areas assist personnel in aligning their tasks with the overarching corporate aim. Modern firms want procurement to provide value in addition to cost reductions. As a result, procurement executives are searching for methods to make the procurement function more sustainable and efficient.

Key Performance Indicators for Procurement

Procurement executives that want to enhance their procurement process rely on various procurement metrics to monitor, assess, manage and improve the procurement function. What is the most critical procurement key performance indicator? Procurement managers choose which KPIs to measure depending on the company’s kind, size, and activities.

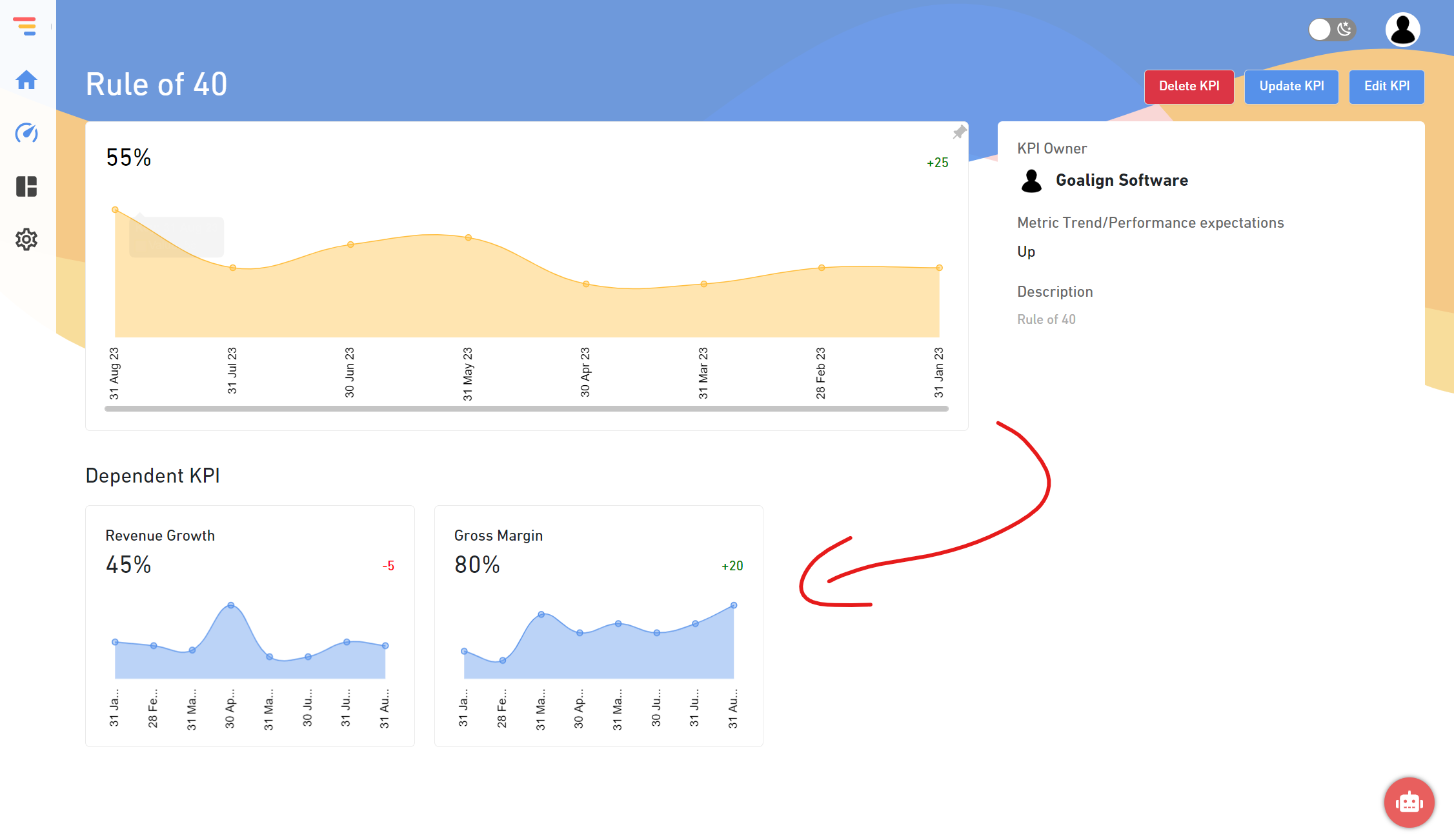

On a dashboard, procurement management software may display different KPI data. For example, a dashboard may show key performance indicators for purchase and supply, supplier performance indicators, and sourcing KPIs.

Procurement KPIs are classified.

As previously said, the KPIs recorded by a company vary depending on the nature and size of the firm and the overall business plan. Businesses must choose baseline KPIs that allow for successful assessment of the procurement function’s performance. The procurement KPIs must be relevant and practical, allowing for effective suppliers, employees, and organizational performance management.

KPIs and Procurement Workflow Automation

Key performance indicators may be used to assess the efficiency of corporate operations. Repetitive and repetitive activities in a corporate process may hurt productivity. Improved company efficiency and performance result from simplified and optimized business processes. Automating critical business processes is excellent for increasing process efficiency and productivity.

Workflow automation eliminates unnecessary stages, resulting in cost and time savings. Workflow automation also includes a unified dashboard for real-time tracking of procurement KPIs. The dashboard of procurement automation software provides management with a bird’s-eye view of all procurement operations.

How Do You Choose Which Procurement KPIs to Use?

There are many KPIs to pick from, but you should limit your list to just those that will genuinely assist in pushing your plan ahead. What is best for you may not be best for the other groups. As a result, we recommend you investigate as many key performance indicators as possible to determine what works best for you. After that, you must integrate the chosen KPIs across your business and align them with your company’s broader plan.

Conclusion

Procurement metrics and key performance indicators (KPIs) are vital in performance management. They may link procurement experts to important strategic points while also increasing insight into each procurement function’s effect and development opportunities. The final result is a well-organized and effective procurement staff equipped to influence the company’s overall performance. While this list is not thorough, it is comprehensive enough to include all of the essential indicators and KPIs that must be considered.